™

CNG

Bus Option

Evaluation

for

the City of Ottawa

Final

Report

January 2007

CNG

Bus Option

Evaluation

for

the City of Ottawa

Final

Report

by

Pierre

Ducharme, DSA

William

Bugyra, LLB, MBA

Roy

Duncan, P.Eng.

David

Martin, P. Eng.

Foreword

This Study was funded by the City of Ottawa with a contribution from the Members of the CNG Consortium. It was managed by Mr. Ken Wetzel, P.Eng., Technical Services Manager for the City of Ottawa.

The research for this Study was undertaken during the months of May, June and July 2006 as the original publication date was set for September 2006. While the publication date was delayed, the Reader should keep in mind that the information contained herein is limited to material available prior to the intended date of publication.

Table of Contents

Foreword___________________________________________________ 2

Table of Contents____________________________________________ 3

Executive Summary___________________________________________ 8

1 Introduction_____________________________________________ 13

1.1 The Context of the

Study_________________________________ 13

1.2 The Objectives of

the Study______________________________ 14

1.3 The Mandate of

sustain-ABILITY™___________________________ 14

1.3.1 Original Mandate___________________________________________________ 14

1.3.2 Changes to the Original Mandate______________________________________ 14

1.4 The Methodology Used

by sustain-ABILITY™___________________ 15

1.4.1 Original Methodology_______________________________________________ 15

1.4.2 Changes to the Original Methodology__________________________________ 16

1.4.3 Note regarding reference documentation_______________________________ 16

2 The CNG Consortium

Case for CNG Buses in Ottawa_____________ 17

2.1 Description of the

CNG Bus Option from a Financial Perspective___ 17

2.2 Strengths and

Weaknesses of the Consortium Business Case for CNG Buses in Ottawa____________________________________________ 19

2.2.1 Logical Structure and Data Accuracy___________________________________ 19

2.2.2 Completeness_____________________________________________________ 20

2.2.3 Validity of Data____________________________________________________ 21

2.2.4 Accuracy of the Original Conclusions___________________________________ 22

2.3 Description of the

CNG Option from an Environmental Perspective 22

2.3.1 Consortium Position________________________________________________ 22

2.3.2 City of Ottawa Staff Position_________________________________________ 22

2.3.3 Supporting Background Information___________________________________ 23

2.4 Strengths and

Weaknesses of the Environmental Case for CNG Buses in Ottawa___________________________________________________ 25

2.4.1 Logical Structure___________________________________________________ 25

2.4.2 Completeness_____________________________________________________ 25

2.4.3 Validity of Data____________________________________________________ 26

2.4.4 Accuracy of Conclusions_____________________________________________ 31

3 The Diesel Electric

Bus Business Case in Ottawa________________ 33

3.1 Description of the

DEH Bus Option from a Financial Perspective___ 33

3.2 Strengths and

Weaknesses of the DEH Case in Ottawa__________ 34

3.2.1 Logical Structure___________________________________________________ 34

3.2.2 Completeness_____________________________________________________ 35

3.2.3 Validity of Data____________________________________________________ 35

3.2.4 Accuracy of the Original Conclusions___________________________________ 37

3.3 Description of the

Diesel Electric Hybrid Option from an Environmental Perspective___________________________________ 37

3.4 Description of the

DEH from an Environmental Perspective______ 37

3.4.1 City Staff Position__________________________________________________ 37

3.4.2 Completeness_____________________________________________________ 37

3.4.3 Validity of Data____________________________________________________ 38

3.4.4 Accuracy of Conclusions_____________________________________________ 43

4 Reconstructed

Business Cases_______________________________ 44

4.1 The CNG Business

Case___________________________________ 44

4.1.1 Capital Costs______________________________________________________ 45

4.1.2 Other Soft, Non-Recurring Costs______________________________________ 54

4.1.3 Summary

of Capital Costs___________________________________________ 55

4.1.4 Operating Costs____________________________________________________ 55

4.1.5 Renewable Fuel Option______________________________________________ 65

4.2 The DEH Business

Case___________________________________ 71

4.2.1 Capital Costs______________________________________________________ 72

4.2.2 Operation Costs____________________________________________________ 73

4.2.3 Renewable Fuel Options_____________________________________________ 75

5 Review of the

Environmental Case___________________________ 77

5.1 Emissions of CNG

buses___________________________________ 77

5.1.1 Compliance with Standards__________________________________________ 77

5.1.2 Performance______________________________________________________ 77

5.1.3 Greenhouse Gases__________________________________________________ 81

5.2 Renewable Fuel

Options_________________________________ 82

5.3 Emissions of DEH

Buses___________________________________ 83

5.3.1 Compliance with Standards__________________________________________ 83

5.3.2 Performance______________________________________________________ 83

5.4 Renewable Fuel

Options (Biodiesel in DEH Buses)______________ 84

5.4.1 Biodiesel__________________________________________________________ 84

5.4.2 Ultra Low Sulphur Diesel_____________________________________________ 86

5.5 Fleet Emissions

Reduction Strategy_________________________ 89

6 Other Issues Related

to Alternate-Fuel Buses in Ottawa_________ 91

6.1 Impact

of New Technologies on CNG and DEH Buses____________ 91

6.1.1 Emissions Control Technologies_______________________________________ 91

6.1.2 Impact on Emissions and Fuel Economy________________________________ 96

6.1.3 Getting to 2010____________________________________________________ 98

6.1.4 Summary_________________________________________________________ 99

6.2 Procurement

of Renewable Fuel Sources in Ottawa___________ 100

6.2.1 HCNG___________________________________________________________ 100

6.2.2 Biogas___________________________________________________________ 100

6.3 Future

Considerations Regarding the Use of New Buses in Ottawa 101

6.3.1 General__________________________________________________________ 101

6.3.2 Evolution of the CNG Technology_____________________________________ 101

6.3.3 Evolution of the Diesel Electric Technology_____________________________ 102

6.4 Common

Practices of Transit Systems Adopting Alternate Technologies 107

6.5 National and International Transit

Acquisition Trends__________ 108

6.6 Other

Considerations Regarding the Adoption of Alternate Technologies______________________________________________ 109

6.7 Pathway to a

Zero-Emission Fleet_________________________ 110

7 Summary of Findings

and Conclusions_______________________ 114

7.1 Financial Components

of the CNG and DEH Options: The Lifecycle Cost of CNG and DEH Buses at the City

of Ottawa_____________________ 114

7.1.1 Summary of Financial and Operational Hypotheses______________________ 114

7.1.2 Calculation Results for the CNG Option________________________________ 119

7.1.3 Calculation Results for the DEH Option________________________________ 120

7.1.4 Sensitivity of the Results___________________________________________ 121

7.2 Environmental

Components of the CNG and DEH Options: Environmental Impact of Using

Alternate-Fuel Buses in Ottawa______ 122

7.2.1 Environmental Performances________________________________________ 122

7.2.2 Consistency with FERS_____________________________________________ 124

8 Recommendations________________________________________ 127

8.1 Financial

Considerations_________________________________ 127

Appendices

Appendix A

Literature Review

Appendix B

List of Responding Transit Systems

Appendix C

Bibliography

Appendix E

Acronyms and Abbreviations

Appendix F

About the Authors

Tables

Table 1 - Total Lifecycle Cost

of CNG Buses vs. Conventional Diesel Buses................... 9

Table 2 - Total Lifecycle Cost of DEH Buses vs. Conventional Diesel Buses................... 9

Table 3 - Operating Costs Forecasted by the Consortium for CNG Buses.................... 18

Table 4 - Lifecycle Costs Forecasted by the Consortium for CNG buses...................... 18

Table 5 - Comparative NOx Emissions Data...................................................... 28

Table 6 - Emissions of CNG vs. Diesel Buses

at WMATA....................................... 29

Table 7 - Intermediate Average Annual Costs for Transit Buses in 2010..................... 31

Table 8 - Operating Costs Forecasted by the Consortium for DEH Buses..................... 33

Table 9 - Lifecycle Costs Forecasted by the Consortium for DEH Buses...................... 34

Table 10 - Emissions of DEH vs. Diesel Buses.................................................... 39

Table 11 - Emissions of DEH vs. Diesel Buses at King County................................... 40

Table 12 - GHG Emissions in CNG

Transit Buses – 2003......................................... 41

Table 13 - GHG Emissions in CNG

Transit Buses - 2010......................................... 41

Table 14 - GHG Emissions in DEH

Transit Buses – 2003......................................... 42

Table 15 - Fuelling Station Cost

Estimates........................................................ 46

Table 16 - City of Ottawa

Transit Garage Comparison.......................................... 51

Table 17 - Garage CNG Upgrading

Costs Parameters............................................ 52

Table 18 - CNG Garage Upgrading

Costs (including taxes)...................................... 54

Table 19 - Capital Cost Summary

for CNG Case.................................................. 55

Table 20 - Forecasted

Electricity Price Increases................................................. 60

Table 21 - Maintenance Costs, Ontario Transit

System, 2001-2005........................... 62

Table 22 - NYC Maintenance

Operations Economics.............................................. 62

Table 23 - WMATA Bus Maintenance

Costs........................................................ 63

Table 24 - Operating Cost

Summary – CNG Fleet................................................. 65

Table 25 - Hydrogen Prices 2007

– 2027 (in $/DLE).............................................. 69

Table 26 - HCNG Lifecycle Costs................................................................... 71

Table 27 - Capital Cost Summary

– DEH Fleet..................................................... 73

Table 28 - Annual Operating Cost

Summary – DEH Fleet......................................... 75

Table 29 - Operating Cost

Summary – Bio-DEH Fleet............................................. 76

Table 30 - Emissions Reduction

in HCNG Bus..................................................... 83

Table 31 - Potential Emissions Reduction from Use of B20 Biodiesel Fuel..................... 85

Table 32 - GHG Reductions from

Different Sources of Biodiesel............................... 85

Table 33 - Emissions Impact of

ULSD.............................................................. 87

Table 34 - Emissions Control Technologies........................................................ 91

Table 35 - Typical Operational

Changes Associated with Alternate-Fuel Buses.............. 107

Table 36 - Transit Buses in Service in the

United States....................................... 109

Table 37 - Two Pathways to Fuel

Cell-Powered Buses........................................... 111

Table 38 - Forecasting

Assumptions for Main Bus Types....................................... 115

Table 39 - NRC and

sustain-ABILITY™ Base Cases for Diesel Buses........................... 117

Table 40 - Annual Variation in

Diesel Prices 2007-2028........................................ 118

Table 41 - Total Lifecycle Cost

of CNG Buses vs. Conventional Diesel Buses................ 119

Table 42 - Total Lifecycle Cost

of DEH Buses vs. Conventional Diesel Buses................ 120

Table 43 - Emissions of CNG vs. Diesel Buses at WMATA...................................... 123

Table 44 - Diesel vs. CNG Emissions on FTP

Transient Cycle.................................. 123

Table 45 - Emissions of DEH vs.

Diesel Buses................................................... 124

Table 46 - Risk Factors

Associated with Alternate Bus Technologies Costs.................. 128

Diagrams

Diagram 1 - Evolving

Emissions Standards................................................... 23

Diagram 2 - Key Characteristics – Diesel vs. NG............................................. 24

Diagram 3 - Key Characteristics – Diesel vs. NG............................................. 24

Diagram 4 - Emissions Controls in 2007 Diesel and NG Engines........................... 30

Diagram 5 - Figure Key Characteristics – Diesel vs. NG..................................... 30

Diagram 6 - Possible Location of Compressor Unit at St-Laurent South.................. 47

Diagram 7 - Ideal Location of Compressor Unit at Merivale................................ 48

Diagram 8 - Recent Natural Gas Prices (2003-2006), in USD............................... 56

Diagram 9 - Natural Gas Prices................................................................ 57

Diagram 10 - Natural Gas Price Variations, 2007-2030 (2007=100)......................... 58

Diagram 11 - CNG Bus Maintenance Costs in $ per Kilometre............................... 64

Diagram 12 - Sources of Hydrogen for HCNG blend........................................... 66

Diagram 13 - In-Service Fuel Economy......................................................... 70

Diagram 14 - Sensitivity

of Lifecycle Cost..................................................... 79

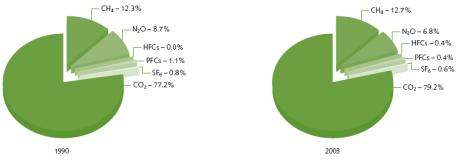

Diagram 15 - Canada’s Greenhouse Gas Emissions........................................... 81

Diagram 16 - HCNG Emissions.................................................................. 82

Diagram 17 - Particulate Filters................................................................. 93

Diagram 18 - Exhaust Gas Recirculation....................................................... 94

Diagram 19 - NOx Compliance Pathways........................................................ 99

Diagram 20 - Fuel Road Map................................................................... 125

Executive Summary

In June 2006,

sustain-ABILITY™ was retained by the City of Ottawa to review the CNG Option, a proposal made by a

Consortium lead by Enbridge Gas Distribution that includes Clean Energy

Fuels, Cummins Westport Inc. and the Canadian Natural Gas Vehicle Alliance. The

objectives of this evaluation are to utilize a reconstructive approach …

Ø to

provide an independent and objective assessment of the CNG Option;

Ø to specifically

validate the financial and environmental components of the CNG Option; and,

Ø to

provide a final report and presentation documenting the findings and

recommendations.

In August 2006, a number of changes were made to

the original mandate to include an evaluation of Diesel-Electric Hybrid (DEH) technologies to provide a comparative

baseline and to evaluate a limited number of issues that were outside the

original scope of work. The evaluation and analysis in this Report were in many

cases constrained or limited by the scope of work and these constraints and

limitations were noted with the Steering Committee throughout the process. This

Report should, therefore, be read in the context of the sustain-ABILITY™

mandate. For clarity, areas where these constraints impacted the conclusions

reached in this report are highlighted, and recommendations for further

analysis are included.

The reconstruction of the CNG business case demonstrates that the Consortium estimates of cost savings generated over the diesel alternative are inaccurate for several reasons:

Ø A logical flaw in their models (the use of $/km data from other transit systems);

Ø Missing cost elements based on parameters of study (such as the cost of adapting transitways to CNG); and,

Ø Invalid capital costs based on parameters of study (the cost of adapting garages to CNG and providing fuelling stations for example).

According to sustain-ABILITY™’s calculations, the savings of $36 million quoted in the business case presented to Council in 2005 would not occur if CNG buses are deployed according to existing deployment patterns from two different garages in Ottawa rather than optimising their deployment. Under this scenario, total costs would increase by $31.2 million or 10.3% over the use of conventional diesel buses on the same routes.

Table 1 - Total Lifecycle Cost of CNG Buses vs. Conventional Diesel Buses

|

Fleet Average |

DIESEL |

CNG |

Diesel vs. CNG |

|

|

|

|

|

$$$ |

% |

|

Capital Investment Costs |

|

|

|

|

|

Bus acquisition |

90,108,581 |

95,366,244 |

5,257,663 |

5.83% |

|

Building and infrastructure cost |

0 |

50,207,748 |

50,207,748 |

|

|

Other soft, non-recurring costs |

0 |

692,074 |

692,074 |

|

|

Total capital costs: |

90,108,581 |

146,266,066 |

56,157,485 |

62.32% |

|

|

|

|

|

|

|

Operating Costs |

|

|

|

|

|

O&M cost (excluding fuel) |

192,698,598 |

193,902,965 |

1,204,366 |

0.62% |

|

Fuel cost |

161,193,810 |

112,051,396 |

-49,142,414 |

-30.49% |

|

Electricity (Compressor) |

0 |

6,293,399 |

6,293,399 |

|

|

Total operating costs: |

353,892,408 |

312,247,760 |

-41,644,649 |

-11,77% |

|

|

|

|

|

|

|

Non-Discounted Total Cost |

444,000,989 |

458,513,826 |

14,512,837 |

3.27% |

|

|

|

|

|

|

|

Discounted Total Cost |

302,108,366 |

333,267,256 |

31,158,891 |

10.31% |

Source: Sustain-ABILITYTM, 2006

It should, however, be noted that a number of assumptions had to be made in the absence of an Ottawa field test of CNG buses and that the Model Year (MY) 2007 will bring significant changes to both diesel and CNG engine technologies.

The review of the DEH business case for the City of Ottawa provided the following results.

Table 2 -

Total Lifecycle Cost of DEH Buses vs.

Conventional Diesel Buses

|

Low Speed / Frequent Stops |

DIESEL |

DEH |

Diesel vs. DEH |

|

|

|

$$$ |

% |

||

|

Capital Investment Costs |

|

|

|

|

|

Bus acquisition |

90,108,581 |

139,816,714 |

49,708,134 |

55.16% |

|

Building and

Infrastructure cost |

0 |

1,763,264 |

1,763,264 |

|

|

Other soft, non

recurring costs |

0 |

955,283 |

955,283 |

|

|

Total capital costs: |

90,108,581 |

142,535,262 |

52,426,681 |

58.18% |

|

|

|

|

|

|

|

Operating

Costs |

|

|

|

|

|

O&M Cost

(excluding fuel) |

246,834,752 |

182,890,809 |

-63,943,943 |

-25.91% |

|

Fuel Cost |

223,774,936 |

163,361,122 |

-60,413,815 |

-27.00% |

|

Battery

replacement cost |

0 |

25,481,952 |

25,481,952 |

|

|

Other costs |

0 |

5,078,268 |

5,078,268 |

|

|

Total operating costs: |

470,609,689 |

376,812,151 |

-93,797,537 |

-19.93% |

|

|

|

|

|

|

|

Non discounted Total Cost |

560,718,269 |

519,347,413 |

-41,370,856 |

-7.38% |

|

|

|

|

|

|

|

Discounted Total Cost |

373,459,512 |

365,250,148 |

-8,209,365 |

-2.20% |

Source: Sustain-ABILITYTM, 2006

For the purpose of this Report, sustain-ABILITY™ was instructed to assume that DEH buses would be assigned to routes where they perform best. The substitution of conventional buses used on low-speed/frequent stops routes in the City of Ottawa would provide the City with savings of $8.2 million dollars (2.2%) as opposed to the $59 million savings anticipated by City staff. This difference is mainly attributable to the fact that the City will not benefit from any subsidy if it acquires DEH buses[1], the expectation that 2007-compliant engines will be less fuel efficient, and that certain increases are anticipated in the cost of diesel fuel. If DEH buses were assigned according to existing deployment patterns, i.e. including less than optimal routes, savings would be further reduced.

The parameters and assumptions used and possible variation of many inputs can influence the outcome of the models reconstructed by sustain-ABILITY™ for the purposes of this study. Unfortunately, performing quantitative sensitivity analysis is beyond the scope of this study. It must be understood however that the 2.2% saving calculated for DEH buses falls well within the margin of error of sustain-ABILITY™’s calculations, in part because the source data provided to sustain-ABILITY™ by the NRC was “of LOW quality.[2]”

The analysis in the Report is also qualified by the fact that certain assumptions had to be made with respect to the potential impact of significant changes in both CNG and diesel engine technologies in MY 2007. The mandate was expanded to include a discussion of expected implications of 2007 technology changes but data on actual performance of 2007 platforms is not yet available.

From an environmental perspective, the case presented in the CNG Option was broadly accurate but incomplete. While both CNG and diesel technologies are designed to meet regulatory requirements, CNG engines are being designed for certification to 2010 levels in 2007, while diesel engine manufacturers are taking advantage of provisions allowing them to phase-in emissions reductions by meeting 50% of the 2010 requirements in 2007. The Consortium case emphasized performance relative to regulated pollutants, while the City’s Fleet Emission Reduction Strategy and City staff analysis focused on CO2 emissions. Additional analysis with respect to CO2 emissions was inconclusive, due to the paucity of quality data and wide variability in the data that was available. Additional constraining factors included the restriction of the analysis to post-2002 CNG technology and restricted scope relating to duty cycles to be considered.

Limited field test data was available for MY 2001 diesel electric buses from the NRC study and sustain-ABILITY™ chose the best results from this study as a basis for comparing DEH buses to CNG buses. Emissions data from previous dynamometer testing of MY 2004 Orion/BAE and MY 2002 New Flyer/Allison DEH platforms was utilized in the NRC study. This data was utilized by sustain-ABILITY™ together with data from the most credible field-testing of newer model DEH buses. Emissions data from the most credible field-testing of newer model CNG engines was utilized and data from a number of other reports was considered. The data suggests that actual performance will vary significantly with engine/chassis combination and duty cycle such that either may perform comparatively better depending on the circumstances, and either may perform only marginally better than clean diesel if not deployed optimally. While DEH buses perform particularly well in a low speed / frequent stops duty cycle, CNG buses offer the greatest benefits in duty cycles characterised by higher speeds / fewer stops. The economic and environmental performance of either DEH or CNG buses will be directly correlated to how optimally they are deployed. Sub-optimal deployment will have significant financial implications and could significantly diminish the potential environmental benefit of investment in these technologies.

Recommendations

Over the anticipated 18-year life of the new buses the City of Ottawa intends to buy, conventional diesel buses would cost between $302 million (if deployed across all routes) and $373 million (if deployed only on low-speed / frequent-stop routes). In that same timeframe, CNG buses deployed across all routes would cost $333 million and DEH buses $365 million (if deployed on low-speed / frequent-stop routes only). These expenditures represent the total net discounted costs calculated by sustain-ABILITY™.

From a strictly financial viewpoint, the lowest cost option for the City of Ottawa in 2007 remains diesel buses[3].

Also from a strictly financial viewpoint, If the City requires buses to operate on their lowest speed / most frequent-stop routes, then it should select DEH buses to perform that duty as long as these buses remain deployed on such routes for their entire lifespan. On the other hand, should the City require buses for average routes or rural ones, conventional diesel buses offer the cheapest alternative. Total disbursements for CNG buses on such routes is however smaller than the cost of deploying DEH buses on low-speed / frequent-stop routes.

The possibility and impact of procuring both the DEH and CNG technologies should be investigated. In this event, the cost of deploying each fleet out of a single garage would be cheaper and, ideally, CNG buses should be located in a new facility built to accommodate the later introduction of hydrogen-fuelled buses.

The introduction of DEH buses in the Ottawa fleet represents the least «disruptive» scenario among those examined by sustain-ABILITY™ in the context of this study because infrastructural changes would be minimal. The use of electric drives in future generations of transit buses is almost certain and the experience gained from working with DEH buses should provide a lasting return on investment.

The adoption of CNG buses, on the other hand, is a bolder step towards an eventual hydrogen/fuel cell fleet. It offers the advantage of the use of an abundant Canadian fuel source at a more predictable price in the future (at least for the next ten years) thereby sheltering the City from potential sharp increases in operating costs that may result from unpredictable oil prices.

The sustain-ABILITY™ Report contains limitations resulting from the scope of the mandate given to sustain-ABILITY™ and from the availability of data in some areas. The impact of these limitations on the level of precision of the quantitative and qualitative conclusions of the report could be material.

Following are the recommendations outlined by sustain-ABILITY™ in the last chapter of this study that would most improve the level of precision of its calculations:

- Refine the comparative diesel base case for both technologies to ensure a fair comparison.

- Adequately characterize Ottawa’s duty cycle.

- Perform quantitative sensitivity analysis of the results and determine the impact of alternative scenarios relating to operation and maintenance costs.

- Perform a detailed study of the impact of 2007 compliance on maintenance costs for DEH buses.

- Test MY 2007 CNG buses in-service in Ottawa assigning the vehicles to routes matching the same variety of duty cycles studied by the National Research Council in its study of DEH buses for Ottawa.

- Participate in testing of MY 2007 diesel and DEH platforms to assess the impact of technology changes.

- Conduct gas flow analysis on St-Laurent South and St-Laurent Station (at the very least) to ascertain facilities upgrade costs.

The City of Ottawa can derive maximum benefit from the above recommendations by incorporating a long-term strategic plan into its considerations. Such a plan would entail the development of a roadmap (ten years or more) to a zero-emission fleet in the overall context of public transportation in Ottawa. The selection of the optimal pathway would then be undertaken within the parameters set in the roadmap.

1 Introduction

1.1

The

Context of the Study

In

2002, the City of Ottawa (the “City”) adopted a Fleet Emissions Reduction

Strategy (FERS) as a part of the City’s efforts to prioritize spending to

improve environmental conditions. The

FERS was revisited and updated in 2004. At that time, CNG was not the preferred

alternative as a mid-term solution in moving toward the prime strategic

objective of zero-emission buses and the City planned to pursue other options,

including diesel-electric

hybrid, for its transit bus fleet.

In the

summer of 2004, Enbridge Gas Distribution approached the City of Ottawa with the

opportunity to review updated information regarding CNG buses.

Efforts

were made through 2004 and 2005 to determine if there were opportunities for

the use of CNG in the transit fleet.

Ultimately a group of CNG industry partners referred to as the Consortium

(Clean Energy Fuels [CE], Cummins Westport Inc. [CWI], the Canadian Natural Gas

Vehicle Alliance and Enbridge Gas Distribution [Enbridge]) brought forward a

business case identifying the potential for a $36 million net present value

(NPV) savings in favour of CNG buses over diesel buses. A presentation in

August 2005 to the City Manager of the Consortium case was focused on four

areas:

1.

Financial

2.

Reliability

3.

Environmental

4.

Directional

Following

a further exchange of information, the City undertook a review of the business

case and reported to the Transportation Committee and Council on the

matter. Report ACS2005-PWS-FLT-0004

resulted in the approval of the following resolution of Council on November 30th,

2005:

1. That the matter be referred to Staff to

arrange a cost-shared independent evaluation of the Compressed Natural Gas

(CNG) Option, both from a financial consideration and from an emissions

perspective, and to report back to Committee by March 2006.

2. That the City Staff explore with the

Consortium and the National Research Council’s (NRC’s) Surface Transportation

Technology Test Facility, the feasibility of running a technical comparison of

CNG Buses with Hybrid Diesel Electric Vehicles for cost effectiveness.

3. That for 2006 the planned purchases of 63

buses be limited to fuel efficient diesel.

The cost-shared

independent evaluation of the Compressed Natural Gas Option was entrusted to

sustain-ABILITY™ following a formal bid process conducted by the City.

1.2

The

Objectives of the Study

In May 2006, the services of

sustain-ABILITY™ were retained by the City to conduct an independent review of

the CNG Option proposing CNG technology for future transit fleet

acquisitions. The objectives of this

evaluation were …

Ø To

provide an independent and objective assessment of the CNG Option;

Ø To

specifically validate the financial and environmental components of the CNG

Option; and,

Ø To

provide a final report and presentation documenting the findings and

recommendations.

More specifically, the acquisition of 226

40-foot buses was to be considered by sustain-ABILITY™.

1.3

The

Mandate of sustain-ABILITY™

1.3.1 Original Mandate

In the start-up meeting of the project, the sustain-ABILITY™ mandate was defined as follows:

Ø sustain-ABILITY™ was to review the financial and environmental aspects of the NGV[4] Option only. The reliability and directional components (relating to the pathway to hydrogen) of the Consortium case and the review/analysis of the diesel and diesel-hybrid options were specifically excluded from the scope of this mandate.

Ø sustain-ABILITY™ was to use a reconstructive approach to analysing the models used to support the NGV Option[5], and to review the business case presented by the Consortium to determine …

o The logical structure used by the Consortium in presenting their business case;

o The completeness of the business case;

o The validity of the business case; and

o The accuracy of the conclusions of the business case.

Only data that relates to newer model engines (post-2002) and CNG buses were to be considered for this analysis. The stakeholders agreed that issues related to earlier model CNG engines were not representative of the products currently being sold.

The City and the Consortium further agreed that all subsidies, taxes and other externalities would be left out of sustain-ABILITY™’s analysis.

The Consortium provided a presentation to Ottawa Council on August 10th, 2005. That presentation, supporting documentation and the cost model developed by Enbridge to support the case, constitute the NGV Option under consideration.

1.3.2 Changes to the Original Mandate

In the course of conducting this study, the Steering Committee decided that the mandate of sustain-ABILTY™ would be expanded to enable a comparison of DEH and CNG technologies and to somewhat broaden the general scope of the analysis. The Steering Committee agreed to amend the scope of work as follows:

Ø Adjustments were made to the reference

prices of CNG buses to ensure their relevance to the City’s specific requirements.

Ø The Urban Dynamometer Driving Schedule

(UDDS) duty cycle was to be used as a common basis for comparing both

technologies from an emissions perspective, rather than characterising different duty cycles that may apply to Ottawa based on

the NRC Report[6] for DEH and

discussing the potential impact on emissions and fuel economy under these duty

cycles based on results from available secondary data sources.

Ø Data on 2005 buses was used to estimate as

best as possible the fuel consumption and emissions of both technologies (CNG

and Diesel Electric Hybrid [DEH]) for 2007 vehicles based on an agreed upon

duty cycle. Manufacturer claims with

respect to plans for 2007 certification were verified to the extent possible

through testing data and educated third-party opinions.

Ø Analysis of the impact on emissions and

fuel economy of various emission control technologies (Ultra Low Sulphur

Diesel, Diesel Particulate Filters with EGR and SCR) was performed based on

manufacturers’ representations, available secondary data sources and

supplemental answers from transit operators. The expected impact of the

introduction of new technologies to ensure CNG and diesel engines meet 2007 and

2010 standards has been included in the report.

Ø Additional field research to ensure costs

obtained from outside sources are as comparable as possible to Ottawa’s

situation (including duty cycle) for CNG buses. Adjustments have been made for

2007 models based on the results of other alternatives presented above.

Ø Updating of the cost of maintaining 2007

DEH buses using the best available data from recent implementations of DEH

buses in service, adjusting for lifecycle increases in these costs over time.

Ø Development of updated prices for CNG

fuelling stations based on a quote provided by Clean Energy that includes

station maintenance costs.

Ø Verification of the cost of fuelling

station maintenance quoted by Clean Energy against field data.

Ø Discussion of the possibility of using

renewable or waste sources of methane and hydrogen without any attempt to

quantify its impact.

Ø Factoring of Ottawa-specific factors (such

as the specific structure of the buildings) in estimates regarding the cost of

upgrading Ottawa’s maintenance facilities. Adjustments were made to field data

information to take such factors into account.

Ø Verification of Ontario’s building code to

determine whether the changes planned to the facilities for DEH buses require

the City to bring HVAC systems to current standards. The results were used to adjust the comparative costs of adapting

the City’s maintenance facilities for both technologies.

Ø Consultation of codes and standards to

determine whether three (3) stations (St-Laurent2, Riverside and

Queensway) used by City buses require modifications if the City acquired CNG

buses. The cost of ventilating these

stations has been included in the CNG business case.

Ø Further

investigation of the use of biodiesel in DEH buses and hydrogen in CNG buses to

outline the general economic

and environmental impact of using these alternate fuels.

Ø General discussion of the pathway to

hydrogen buses included in the report (without any attempt to quantify its

implications) to provide a long-term perspective to the reader.

1.4

The

Methodology Used by sustain-ABILITY™

1.4.1 Original Methodology

sustain-ABILITY™ developed a specific methodology based on the Request for Proposal (RFP) submitted by the City of Ottawa and the proposed project team's expertise and experience in the field.

sustain-ABILITY™ proposed a Reconstructive Approach consisting of a close examination of the CNG Option of the Consortium’s Business Case submitted by the Stakeholders in order to …

Ø ascertain its logical consistency;

Ø determine its completeness;

Ø validate input data used in the Business Case; and,

Ø verify the accuracy of the calculations supporting the arguments.[7]

1.4.2 Changes to the Original Methodology

In the course of the project, the Stakeholders agreed that the level of precision of the Study should be increased in certain areas to provide a better basis for comparing the two competing technologies. Additional research was therefore conducted to provide the complementary information described in section 1.3.2.

The additional information enabled a comparative analysis of the two competing technologies (CNG and DEH). It also provided the data necessary to evaluate variations on the basic technologies, such as adding hydrogen to CNG and using biodiesel fuel in DEH, and to comment on the advantages of each technology in the context of the prime strategic objective of zero-emission buses.

1.4.3 Note regarding reference documentation

A significant amount of information was provided by City Staff to sustain-ABILITY™ in the course of this Study, including the report of a study performed by the National Council of Canada . sustain-ABILITY™ did not gather data directly, nor has the accuracy of the data provided by the City for the purpose of this study, or the study conducted by the NRC, been verified.

With the exception of updating minor elements related to cost information contained in the NRC Report, the scope of sustain-ABILITY™’s mandate did not include a critical review of the study. Therefore, the accuracy of the NRC findings was not questioned and much of its content was used as the basis for comparing the performance of DEH buses to that of CNG buses.

2 The CNG Consortium Case for CNG Buses in Ottawa

2.1

Description

of the CNG Bus Option from a Financial Perspective

The Consortium provided sustain-ABILITY™ with two different models (dated August 2005) as well as two updates of those models (dated December 2005). The incremental costs used in the models were based on absolute numbers in one case (“The Pierce-based model”) and on a 20% increase over regular Diesel O&M costs (“The 20% model”).

Both models are based on common working

hypotheses:

Ø The

City of Ottawa will purchase 226 buses (68 in 2007, 80 in 2008 and 78 in 2009);

Ø The

life of a bus is 18 years;

Ø The

buses are to be maintained and stored at a single facility;

Ø Each bus operates 75,000 kilometres per year;

Ø A

discount factor of 6.75% was used for the Net Present Value analysis;

Ø The CA$ to US$ exchange rate used was 1.40 $ Canadian = 1 $ US.

The following sources were used to form the basic assumptions of the CNG Consortium cost models:

|

Ø

Fuel

Consumption of CNG buses |

Ten

Years of Compressed Natural Gas (CNG) Operations at SunLine Transit Agency April 2003 — December 2004 K. Chandler Battelle, Columbus NREL/SR-540-39180 |

|

Ø Natural Gas Prices |

Enbridge

Rate Sheet dated April 1, 2005 |

|

Ø Facilities Upgrade |

Bus Facilities Requirements

Study for Alternative Fuel Buses, Final Draft Report prepared for the Toronto Transit

Commission January 19, 2005 McCormick Rankin Corporation 2005 |

|

Ø Fuelling Infrastructure |

Idem (McCormick Rankin Corporation 2005) |

|

Ø Operations & Maintenance Costs |

Pierce Transit: The Future

is Clear: 100% CNG fleet Cummins Westport Promotional Literature (Undated) |

The key modelling assumptions made by the Consortium regarding CNG buses are the following:

|

Ø

Fuel

Consumption of CNG buses |

3.08 (Sunline)

to 3.10 (TTC) miles per diesel gallon equivalent. The Consortium used 0.76

diesel litres equivalent per km (or 3.1 miles per diesel gallon equivalent). |

|

Ø

CNG Prices |

Natural gas is

$0.26/km. The electricity required by the fuelling station adds 1.6 cents/km

for a total CNG fuel price of $0.277/km. |

|

Ø

Facilities

Upgrade |

Average cost to

upgrade the facilities for CNG buses and fuelling is $13.3 million |

|

Ø

Operations

& Maintenance Costs |

US$0.16 per mile

(Pierce) or CA$0.14 per km |

|

Ø

Compressor

Maintenance Costs |

$0.03 per km |

The financial analysis of operating costs supplied by the Consortium is presented following.

Table 3 - Operating Costs[8] Forecasted by the

Consortium for CNG Buses

|

The Pierce-based Model |

August and December 2005 |

||

|

Cost Category |

$ per km |

$ per |

Total Fleet Cost

($) |

|

O&M Cost (excluding fuel) |

0.14 |

10,500 |

2,373,000 |

|

Fuel Cost |

0.28 |

20,775 |

4,695,150 |

|

Compressor Maintenance Cost |

0.03 |

2,250 |

508,500 |

|

Total Cost |

0.45 |

33,525 |

7,576,650 |

Source: CNG Consortium, 2005

|

The 20% Model |

August and December 2005 |

||

|

Cost Category |

$ per km |

$ per |

Total Fleet Cost

($) |

|

O&M Cost (excluding fuel) |

0.23 |

17,100 |

3,864,600 |

|

Fuel Cost |

0.28 |

20,775 |

4,695,150 |

|

Compressor Maintenance Cost |

0.03 |

2,250 |

508,500 |

|

Total Cost |

0.54 |

40,125 |

9,068,250 |

Source: CNG Consortium, 2005

On a lifecycle basis that includes capital costs, the Consortium forecasted the following savings when comparing CNG buses to conventional Diesel buses:

Table 4 -

Lifecycle Costs Forecasted by the

Consortium for CNG buses

|

The Pierce-based Model |

August 2005 |

December 2005 |

|

Capital Investment |

|

|

|

40-foot bus savings1 ($) |

42,940,000 |

4,016,020 |

|

Building and Infrastructure incremental

cost ($) |

(13,500,000) |

(13,500,000) |

|

Operating Cost Savings ($) |

81,766,800 |

81,766,800 |

|

Net Savings of CNG Over

Diesel ($) |

111,206,800 |

72,282,820 |

|

Discounted (6.75%) Savings

of CNG Over Diesel ($) |

73,124,043 |

36,716,490

|

1 Assuming subsidies from the Government of

Ontario for urban transit vehicles and alternate fuel buses.

|

The 20% Model |

August 2005 |

December 2005 |

|

Capital Investment |

|

|

|

40-foot buses savings* ($) |

42,940,000 |

4,016,020 |

|

Building and Infrastructure incremental

cost ($) |

(13,500,000) |

(13,500,000) |

|

Operating Cost Savings ($) |

54,918,000 |

54,918,000 |

|

Net Savings of CNG Over

Diesel ($) |

84,358,000 |

45,434,020 |

|

Discounted (6.75%) Savings

of CNG Over Diesel ($) |

57,868,486

|

21,460,933 |

Source: CNG Consortium, 2005

* Assuming subsidies from the Government of

Ontario for urban transit vehicles and alternate fuel buses.

The variations between the August and December forecasts in both models occur as a result of a change in savings related to the purchase of the buses. Adjustments were made by the Consortium to reflect the impact of subsidies and sales taxes from the Government of Ontario.

Depending on the model used, savings over the cost of using conventional diesel buses ranging from $21.5 to $73.1 million would result from the placing in service of a CNG fleet of 226 buses in Ottawa.

2.2

Strengths

and Weaknesses of the Consortium Business Case for CNG Buses in Ottawa[9]

2.2.1 Logical Structure and Data Accuracy

The logical structure of the models developed by the Consortium comprises all major cost components. Without the full benefit of all internal cost data from the City at the time of its construction, the model was based on differential costs. Various sources have been used to obtain incremental (higher or lower) costs associated with the use of CNG buses as compared to diesel and diesel-electric hybrid buses. The Consortium states it has attempted to be conservative in its estimates but it could not arrive at accurate estimates for the following reasons:

Ø The Consortium model does not replicate the baseline case of the City of Ottawa. In order to perform a comparative analysis, the situations being evaluated must be identical or adjustments must be made to bring them to a comparable basis. This is very difficult under the best of circumstances as the number of variables to be considered is somewhat overwhelming: weather conditions, duty cycles, operating procedures, labour contracts, etc.

Ø From a logic perspective, using absolute numbers in the form of $/km presents the problem that some significant elements such as labour costs (and therefore the shop rates), of the reference cases are different from those of the City of Ottawa. In the case of maintenance costs, for example, the equation would read:

$/km = (hours required * shop rate)/km driven

Using the absolute $/km at Pierce Transit as a reference case to determine the maintenance costs in Ottawa does not take into consideration the differential in shop rates.

Ø Using a percentage differential (the second model used by the CNG Consortium uses 20% and the accuracy of this figure will be discussed later) avoids the problem of unavailable detailed inputs as long as the overall costs (the current maintenance cost per km in the example) are available.

The Consortium assumed that only one facility would be converted to host CNG buses. The common practice at the City of Ottawa is to distribute new buses among various garages for several valid reasons (equal distribution of the maintenance load, fair distribution of new buses among the various routes, etc). The conversion of only one facility does not follow the logic of the process currently used at the City of Ottawa where management Staff would prefer to maintain more flexibility. This does not necessarily invalidate the use of a single garage in the short term with a second facility being converted at a later date, especially if the City of Ottawa chooses to convert an increasingly larger proportion of its bus fleet to a lighter than air gaseous fuel.

2.2.2 Completeness

A model is regarded as complete when all relevant cost elements have been taken into consideration.

The models submitted by the CNG Consortium asserted that the following elements were taken into consideration:

Ø Fuel Consumption of CNG Buses

Ø Natural Gas Prices

Ø Facilities Upgrade (Capital costs)

Ø Fuelling Infrastructure

Ø Operations & Maintenance Costs

Generally speaking, these represent all the major elements of converting a diesel bus fleet to a CNG bus operation. The fuel consumption and price of natural gas estimates are complete.

As the method used to determine the potential savings of adopting CNG buses was based on cost differentials, it is not possible to determine precisely if all cost elements specific to the City of Ottawa were taken into consideration in the facilities upgrade category as detailed data on the changes required to the reference properties is not available. However, converting a single existing garage will not suffice to the task of handling new CNG buses as many specialised tasks are performed in separate facilities. For example, the engine dynamometer room and the body overhaul facility located at St-Laurent South would need to be converted to CNG even if another facility would be selected to host the CNG fleet. This was not taken into account in the Consortium models. In this respect, they are incomplete.

Transitway stations have not been integrated in the models proposed by the Consortium. If new CNG buses are required to be available on these transitways, three stations will be affected: the St-Laurent Station, the Riverside Station and the Queensway Station.

As for fuelling infrastructure, CNG buses can be deployed from only one facility as foreseen in the Consortium model. The cost of fuelling infrastructures used in the models is based on the average cost of converting the Toronto Transit Commission (TTC) facilities in 2004.

It is not possible to fully assess the completeness of the estimate used by the Consortium as it is based on an average of facilities. The cost of new refuelling facilities is very site specific. Without the benefit of detailed information at the time the model was built, the Consortium could not estimate the cost associated with facility conversion. The estimate used by the Consortium excluded the cost of upgrading the HVAC system on the basis that this upgrade (in the TTC case) should be performed regardless of the introduction of CNG buses, as the facilities do not meet current HRAI standards. In the course of the study, Ottawa’s property managers assured sustain-ABILITY™ that most of the City’s facilities do meet current standards[10].

References to elements contained in the cost of operation and maintenance are not detailed in the CNG Consortium model nor are they detailed in the main source provided for the information (Pierce Transit). An opinion concerning the completeness of this cost category cannot therefore be formulated.

2.2.3 Validity of Data

Data is considered valid when it is applicable to the City of Ottawa situation and accurate. The cost of CNG fuel used in the Consortium model is based on several valid assumptions:

Ø Bus performance = 3.1 miles/diesel gallon

equivalent (because the average duty cycle of the Ottawa fleet was assumed to

be comparable to that of the TTC);

Ø Natural gas prices are based on Enbridge

tariffs effective at the time the case was developed;

Ø Electricity required for compression of NG

($0.016/km) was based on Ottawa Hydro tariffs as applicable to the City at the

time the case was developed.

The capital costs of a fuelling station provided by the Consortium are not valid. This may be explained by the lack of site-specific data available to the Consortium at the time the model was constructed. In the course of this project, the Consortium was supplied with detailed information resulting in Clean Fuels Energy providing a valid cost estimate of supplying the City of Ottawa with two fuelling stations for specific sites. This information will be used in the reconstruction of the business case presented later in this report.

The same conclusion applies to the cost of bringing the City’s facilities up to CNG standards. Again here, this exercise is very site specific and the Consortium did not have access to the data required. As the Consortium could not identify the garage where the CNG fleet would be hosted, it selected an average cost of upgrading the TTC facilities. This provided a first-order summary that is, however, insufficient for decision-making purposes. A more precise estimate will be included in the reconstructed model presented later in this report.

The Consortium used O&M costs from Pierce Transit as a reference for both models. In the opinion of sustain-ABILITYTM, this information is not valid despite the fact that Pierce has almost the same average commercial speed as Ottawa[11], and the fact that generally, O&M costs are correlated with the average speed of the fleet. First, the shop rate of Pierce ($98)[12] is different from that at Ottawa Transit ($71). The information regarding the O&M cost per mile obtained from Pierce Transit by the Consortium was confirmed by the research undertaken by sustain-ABILITYTM but remains inexplicably low. Pierce Transit did not provide sustain-ABILITY™ sufficient data to substantiate the accuracy of this information. Excluding Pierce Transit from the sample, the maintenance costs obtained by sustain-ABILITY™ in its survey of transit systems range from $0.29 to $0.90/km while the cost used in the Consortium business case is $0.14/km.

In addition, all O&M CNG C-Plus Gas engine cost data obtained was necessarily tabulated from relatively young fleets as this engine model has been on the market for only four years. Experience shows that average bus maintenance costs increase dramatically in the first five to six years of a bus’ life and peak afterwards.

The overall validity of the data used in the Consortium models is therefore questionable in these respects and will be revised in Section 4 of this report.

2.2.4 Accuracy of the Original Conclusions

Given the incompleteness of the models presented by the CNG Consortium and the inaccuracy of several cost elements in the Ottawa context, the potential savings the City will realize by introducing CNG buses as presented in the Consortium’s business case are not entirely relevant.

Section 4 provides reconstructed cost estimates while Section 7 draws conclusions regarding the CNG option.

2.3

Description

of the CNG Option from an Environmental Perspective

2.3.1 Consortium Position

The Consortium Case from an environmental perspective (the “CNG Option”) was represented as follows:

Ø

CNG is the cleanest available solution

o CNG engines and vehicle platforms offer the lowest urban emissions;

o substantial greenhouse gas emission reductions are generated using a CNG platform relative to diesel;

o hybridisation would enhance these benefits proportionally to those claimed for hybridisation of diesel engines.

Ø Stricter emissions standards reduce diesel efficiency, reliability and drive up costs

o ever-tightening emissions standards (Environmental Protection Agency [EPA] and California Air Resources Board [CARB]) are difficult for diesel to achieve;

o the technology used to reduce diesel emissions reduces efficiency and reliability and increases costs.

Ø Low sulphur diesel fuel requirements drive up costs and potentially reduce efficiency and increase maintenance costs

Ø “Clean” DEH technology carries uncertainty

o ability to meet regulations (currently engine, not platform, based) and diesel faces significant challenges to get to 0.2g NOx standard;

o novelty of hybrid drive systems;

o reliance on subsidy to be economic.

2.3.2 City of Ottawa Staff Position

Natural gas buses (the NGV Option),

according to City

Staff, present no environmental benefit compared to DEH buses for

the following reasons:

Ø Diesel-electric hybrids operating under severe duty cycles (assessed as comparable to those recommended by NRC for use in Ottawa) produce fewer emissions than CNG buses;

Ø Hybrid buses have an advantage in non-regulated emissions such as greenhouse gases (GHGs) (this has significant relevance in Canada that has ratified the Kyoto Protocol, whereas the USA has not);

Ø CNG has no renewable fuel option, such as bio-fuels.

2.3.3 Supporting Background Information

The Consortium environmental case was embodied in an MS PowerPoint presentation[13] (the “Consortium Presentation”) without supporting written documentation. There is no written record of the discussion that accompanied the presentation. This section documents the Consortium case based on subsequent communications between the Consortium and City Staff and communications between sustain-ABILITYTM and Consortium members.

Diagram 1, extracted from the Consortium Presentation, was developed by Cummins-Westport and similar graphics appear throughout the literature sustain-ABILITY™ has reviewed. It illustrates the evolving EPA emissions standards for Nitrogen Oxides (NOx) and Particulate Matter (PM) over time, the current emissions levels, and levels that must be achieved for 2007 and 2010. The blue 2002 box represents emissions standards currently in effect. The dark green box in the lower left-hand corner shows the 2007 regulations that must be fully met by 2010. The gold box indicates the blended average that must be met starting in 2007 as the 2010 levels are phased in. The numbers to the right of the graph indicate the lower levels of sulphur permitted in diesel fuel and the estimated incremental increase in cost for diesel to meet each level of tighter emissions standards.

Diagram 1 -

Evolving Emissions Standards

Evolving Emissions Standards

CWI has indicated that it expects to certify its 2007 engines to the 0.2g NOx 2010 regulations in Q1 2007. It expects diesel engine manufacturers to initially certify to the 1.2g NOx average and require additional improvements to meet 2010 requirements. A description of the regulations and phase-in requirements follows.

CWI has developed a lifecycle cost model that incorporates the expected cost of meeting evolving environmental standards, as well as the associated impact on engine performance, and has offered to work through it with City Staff. It should be noted that CWI has indicated that the model itself cannot be provided to sustain-ABILITYTM as it contains proprietary Cummins Inc. data.

Diagram 2 is also included in the Consortium Presentation. It is proposed that the performance of CNG engines relative to comparable diesel platforms has improved markedly, such that 2001 CNG engine technology is considered by Cummins Westport to be equivalent to diesel, save emissions where the CNG technology is better. It is projected that fuel cost / mile and lifecycle cost will also be better in the new 2007 engine platform. Reliability and durability are expected to continue to be similar to diesel. It is the position of the Consortium that CNG technology had problems in its introductory years but that it is now a mature technology. It is claimed that modern CNG buses significantly reduce emissions while being very comparable to diesel in operating costs.

Diagram 2 - Key Characteristics – Diesel vs. NG

|

|

L 10 G |

C 8.3 |

C

Plus |

2007

Gas |

|

Emissions |

Better |

Better |

Better |

Better |

|

Reliability |

Worse |

Worse |

Similar |

Similar |

|

Fuel Cost/Mile |

Worse |

Worse |

Similar |

Better |

|

Durability |

Worse |

Worse |

Similar |

Similar |

|

LCC |

Worse |

Worse |

Similar |

Better |

|

Timeline |

1989 |

1996 |

2001 |

2007 |

Source: Cummins

It is also the Consortium’s position that the current trend in increasing diesel fuel prices is not likely to reverse. Ultra Low Sulphur Diesel now being implemented, coupled with increasingly stringent requirements for diesel engine emissions controls scheduled for 2007 and 2010, will make diesel buses more expensive to operate in the future. The technology required to clean up emissions to current levels (i.e. particulate traps) has already negatively impacted reliability, and it is not yet known how the lubricity of Ultra Low Sulphur Diesel (ULSD) (to protect the engine) will be achieved. The cost of fuel, however, is expected to be significantly higher than standard diesel.

Cummins Westport has indicated, as shown in Diagram 3, that future diesel-powered buses will actually lose fuel economy in the attempt to make them less environmentally damaging. Diesel buses are most efficient operating at high temperatures but this also generates the most pollution. Thus reducing combustion temperatures to protect the environment will also reduce fuel economy.

Diagram 3 - Key Characteristics – Diesel vs. NG

The Consortium also cited problems that the

Toronto Transit Commission (TTC) had with diesel particulate filters to support

its case that emissions control devices required to permit diesel to meet

emerging emissions standards would reduce reliability and increase cost. The

TTC authorized additional funds to allow the

first 80 buses of the 330-bus order to be delivered with Diesel Oxidizing

Catalyst exhaust after-treatment instead of the Diesel Particulate Filters

(DPFs) originally specified. Based on the experience of other transit

properties, such as Ottawa and Golden Gate in California, it has become evident

that the introduction of DPFs to large fleets is premature and is leading to

high filter maintenance and reduced availability of buses for service.[14]

2.4

Strengths

and Weaknesses of the Environmental Case for CNG Buses in Ottawa

2.4.1

Logical

Structure

The Consortium’s environmental case focuses on regulated pollutants: the basis upon which technical performance specifications are established and technologies are certified.

The Consortium case focuses on engine emissions versus vehicle-based emissions. This is also consistent with the way emissions are regulated and technologies are certified today. Implicitly, the Consortium case is based on the standardised duty cycle used for the purpose of engine certification.

The Consortium case does not directly address greenhouse gases and does not consider the impact of the local duty cycle on actual versus certified emissions, nor does it expressly consider the potential impact of hybridisation of the diesel platform.

The Consortium case is not necessarily illogical with respect to its focus on regulated emissions from the engine, but it could be characterised as incomplete from the City Staff perspective, as discussed in the following section.

Ottawa’s Fleet Emissions Reduction Strategy

specifically references a reduction in CO2 emissions and adopts the

recommendation of City Staff to pursue diesel-electric hybrid buses instead of

CNG buses. It is illogical that the Consortium’s case would not address the

comparative advantages and disadvantages of both technologies. The failure to

consider the local duty cycle is also illogical, given that the City measures

emissions reduction on the basis of fuel consumption.

2.4.2

Completeness

Consistent with the criteria used to assess the business case, the environmental case would be regarded as complete when all relevant elements have been taken into consideration.

The environmental case is described in very general terms. There is very little in the way of explanation or support for the claims made in the documentation provided. However, as noted above, the materials included a PowerPoint presentation that would have been accompanied with a verbal explanation. Section 2.3.3 is included for that purpose.

It was acknowledged that the greenhouse gas emissions issue was not specifically addressed in the Consortium presentation, and that Cummins Westport’s focus, like that of other engine manufacturers in the industry, has been on regulated emissions. Consortium members subsequently provided data available to them as part of the supporting documentation required to validate their case.

It was also acknowledged that no analysis had been undertaken to determine the impact of the Ottawa duty cycle on the emissions profile of the CNG bus. The Consortium position is that all engine manufacturers are required to certify to the same regulated emissions targets, and that the certification tests consider a representative duty cycle adopted by the regulators. The UDDS duty cycle, ultimately agreed-on as the baseline for this study, has been developed for chassis dynamometer testing of heavy-duty vehicles and was the basis for the development of the Federal Test Procedure, or FTP, transient cycle used for EPA certification. The FTP transient test was developed to take into account the variety of heavy-duty trucks and buses in American cities, including traffic in and around the cities, on roads and expressways.[15]

As noted above, the CNG Option, as originally presented, was incomplete as it failed to adequately address GHG emissions and the local duty cycle. The Consortium could not reasonably have been expected to characterise an Ottawa duty cycle in the context of presenting the CNG Option and it was ultimately agreed with the City not to include such an analysis in this Report. Nevertheless, the potential impact could have been addressed given the availability of the NRC Report that discusses the impact of duty cycle on the potential benefit of DEH buses without characterising an “Ottawa duty cycle”.

2.4.3

Validity

of Data

Data

is considered valid when it is accurate and applicable to the situation of the

City of Ottawa. Given the general and

high-level nature of both the Consortium and City Staff positions with respect

to the environmental case, an assessment of the validity of their respective

positions and accuracy of their conclusions required substantial primary and

secondary research. In fact, the third-party data is sufficiently inconsistent

that conclusions supporting a broad range of positions can be drawn. Engine,

vehicle, model, model year, duty cycle and test parameters can have a dramatic

impact on results. The (sometimes poor) quality of data acquisition and

reporting and the lack of timely reporting of current data in an environment of

rapidly changing technology to meet 2007 regulatory requirements are also

factors.

The

sources of third-party data vary, from independent testing by government

organizations based on established protocols and methodologies to private

studies prepared by consultants in accordance with less stringent and

transparent data collection, analysis and reporting methods. The highest

quality data available is from fleet testing undertaken by the National

Renewable Energy Laboratory (NREL) in the United States. Each of its studies is

carried out in accordance with a General Evaluation Plan, Fleet Test and Evaluation Projects[16].

Recent studies were carried out by NREL in collaboration with other

national laboratories, universities and government staff for the Washington

Metropolitan Area Transit Authority (WMATA), King County Metro Transit

Authority (KCMTA) in Seattle, and the New York City Transit Authority (NYC).

Testing undertaken by Environment Canada (referenced in the NRC Report) was

also undertaken and reported in a similarly thorough manner.

The

use of studies undertaken by Levelton Consultants (for BC Transit), TIAX (for

CARB), MJ Bradley and Associates (for the Massachusetts Bay Transportation

Authority) and Parsons Brinkerhoff for Sound Transit (suburban Seattle,

Washington) is qualified and limited, for the reasons described in the

summaries provided in Appendix 1. Some other sources provided by the

stakeholders, including the Northeast Advanced Vehicle Coalition Hybrid

Electric Drive Heavy-duty Vehicle Testing Project[17]

cited by City Staff in the FERS Update, are outdated and outside of the

parameters agreed by the stakeholders for this evaluation. The City has also

referenced a recently completed Bus Technology and Alternative Fuel

Demonstration Project conducted by MJ Bradley and Associates for Translink (the

“Translink Study”). Unfortunately, the final report from that study was not

available when this Report was being prepared and the preliminary data that had

been released was incomplete. The preliminary Translink staff reports raise a number

of flags with respect to the methodology used and whether the buses used fall

within the parameters agreed for this evaluation (as discussed in Appendix 1).

It is our understanding that Translink is planning to re-do its testing with

2006 model CWI CNG and Diesel buses beginning in November.

Additional

data was acquired directly from transit agencies, academic institutions

specializing in automotive technologies, the US EPA, NREL, Environment Canada

and Southwest Research Institute (SwRI), an independent research and testing

organization that it is widely utilized by engine manufacturers and respected

in the industry.[18]

As

noted, the claims in the Consortium base case were very high level and

generally unsupported by reference to verifiable sources. The Consortium’s

position is that its case was intended to raise the major issues, with the

intent of subsequently carrying out a more complete analysis in the specific

Ottawa context. The additional background information buttresses the Consortium

case but is incomplete in that it does not address greenhouse gas emissions (a

declared priority in the Ottawa FERS) with specific data. It also focuses on

comparisons to diesel rather than the diesel-electric hybrid alternative, in

some cases drawing conclusions without relevant supporting data or reference

points, and it fails to address inconsistencies in publicly-available data

where such data contradicts its case.

Where the Consortium case proposed that CNG is the cleanest available solution, “clean” is not defined specifically, but is characterised as regulated, pollution-causing emissions. In January 2001, the United States Environmental Protection Agency enacted the latest round of regulations for the “Control of Air Pollution from New Motor Vehicles: Heavy-Duty Engine and Vehicle Standards and Highway Diesel Fuel Sulphur Control Requirement”.

“Even with more stringent

heavy-duty highway engine standards set to take effect in 2004, these engines

will continue to emit large amounts of nitrogen oxides and particulate matter,

both of which contribute to serious public health problems in the United

States. These problems include premature mortality, aggravation of respiratory

and cardiovascular disease, aggravation of existing asthma, acute respiratory

symptoms, chronic bronchitis, and decreased lung function. Numerous studies

also link diesel exhaust to increased incidence of lung cancer. We believe that

diesel exhaust is likely to be carcinogenic to humans by inhalation and that

this cancer hazard exists for occupational and environmental levels of

exposure. We are establishing a comprehensive national control program that

will regulate the heavy-duty vehicle and its fuel as a single system. As part

of this program, new emission standards will begin to take effect in model year

2007, and will apply to heavy-duty highway engines and vehicles. These

standards are based on the use of high-efficiency catalytic exhaust emission

control devices or comparably effective advanced technologies. Because these

devices are damaged by sulphur, we are also reducing the level of sulphur in

highway diesel fuel significantly by mid-2006.”

(40 CFR Parts 69, 80, and 86, January 18, 2001)

As Table 5 and Diagram 4 from SwRI show, CNG engines have traditionally demonstrated superior capabilities to achieve lower levels of NOx and PM emissions, and NOx plus Non-Methane Hydrocarbons (Methane itself does not contribute the formation of smog). This has been demonstrated by lower certified emissions levels and is broadly reflected in the literature with respect to in-service testing. In 2007, the difference between diesel and gas engines will be at its highest level in 20 years, on a percentage basis, albeit at low levels. If, as has been suggested, the City purchases 2006 diesel engines for the first wave of new DEH bus purchases in 2007, certified NOx emissions may be more the twelve times higher than with 2007 CNG and PM emissions may be up to five times higher. For the 2008 and 2009 purchases, base NOx emissions will continue to be six times higher than with 2007 CNG engine buses but the new diesel engines will have to comply with the 0.1g PM standards.

Table 5 - Comparative NOx Emissions Data

|

Gas Traditionally Ahead of Diesel |

||

|

Model Year |

Diesel Engines |

Gas Engines |

|

1988 |

10.7 |

n/a |

|

1990 |

6.0 |

2.5 |

|

1994 |

5.0 |

2.5 |

|

1998 |

4.0 |

2.5 |

|

2002-2004 |

2.4/2.5 |

1.8 |

|

2007 |

1.18 |

<0.2 |

|

2010 |

0.2 |

<0.2 |

Source: SwRI, 2006

Notwithstanding the foregoing, the City has

indicated that it is more concerned about CO2 emissions of its in-service

fleet. The

NREL-WMATA study is the only available independent study of new CNG engine

technology in field service.[19] The relevance of the results of this study

is subject to the following qualifications:

the data sample is limited, a WMATA specific duty cycle was

characterised that may not be directly comparable to the UDDS cycle and the

study utilized both newer and older model CNG and diesel platforms. However, in accordance with the project

scope and evaluation parameters, only newer model results are used. The older

model CWI CNG buses did not perform as well as newer model Deere platforms on

regulated emissions, but performed very well with respect to CO2

emissions.

The

following table indicates that the new model CNG buses performed well compared

to new model conventional diesel buses equipped with the latest emission

controls.

Table 6 - Emissions of CNG vs. Diesel Buses

at WMATA

|

Vehicle |

CO (g/mile) |

NOx (g/mile) |

Methane (g/mile) |

Non-Methane Hydro-carbons (g/mile) |

PM (g/mile) |

CO2 (g/mile) |

|

MY 2004 DDC Series 50 With EGR and DPX |

.34 |

17.9 |

|

0.003 |

.025 |

3346 |

|

MY 2004 John Deere 6081H CNG with Oxidation Catalyst |

.14 |

9.08 |

10.6 |

0.55 |

.004 |

2173 |

|

CNG Emissions as % of

Diesel |

41% |

51% |

|

18,333% |

16% |

65% |

* Total Hydrocarbons – Methane plus non-methane

hydrocarbons

Source: NREL, 2005

The John Deere CNG buses produced 59% lower CO, 49% lower NOx emissions, 84% lower PM and 35% lower CO2 emissions compared with the MY 2004 DDC diesel buses. Older model Cummins Westport equipment did not perform as well in some respects. However, this was acknowledged by the Consortium and the scope of the sustain-ABILITYTM analysis was defined to exclude pre-2002 equipment.